Sep 05, 2013

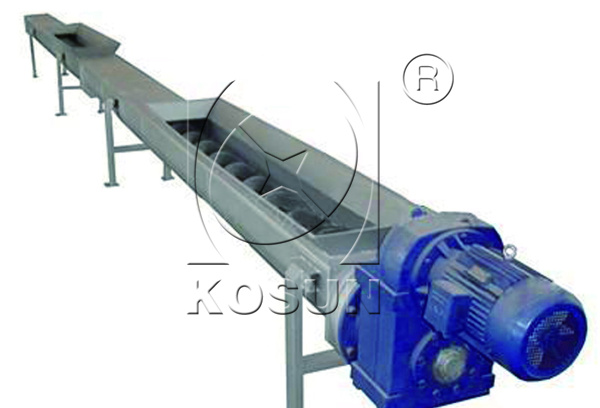

A screw conveyer or auger conveyor is a mechane that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyers in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water.

They usually are consisted of a trough or tube containing either a spiral blade coiled around a shaft, driven at one end and held at the other, or a " shaftless spiral", driven at one end and free at the other. The rate of volume transfer is proportional to the rotation rate of the shaft. In industrial control applications, the device is often used as a variable feeder by varying the rotation rate of the shaft to deliver a measured rate or quantity of materials into a process.

Screw conveyers can be operated with the flow of materials inclined upward. When space allows, this is a very economical method of elevating and conveying. As the angle of inclination increases, the capacity of a given unit rapidly decreases. The rotating part of the conveyor is sometimes called simply an auger.

Screw conveyer, commonly known as auger. It has horizontal, inclined and combined form, and it can be used with other transport devices, to accomplish combined transport, separate transport, mixing, blending, dehydration, compounding, discharging and stacking, etc. KOSUN Screw Conveyer is used in the drilling waste management for the drilling fluids or cuttings transportation.

Features & Benefits

1. It has compact structure, small cross section, light weight, good sealing performance, highly efficient transportation, flexible technological layout, with ease of installation, dismantlement, motion and safe operation.

2. It is applicable to transport various kinds of soft materials such as powder, granular and small pieces of materials for example: clay, powder, pulverized coal, cement, sand, grain, small pieces of coal, cobble, cast iron filings, etc.

3. It is not applicable to transport materials that is of high viscosity and is easy to be curdled.

The waste produced by drilling operations, if not treated properly, will cause great harm to the envioronment, that is why more and more countries begin to set up regulations to minimize the oil on cuttings, so that the drill cuttings can be reused or discharged.

Apart from solids control equipment, KOSUN can also manufacture various drilling waste management equipment, such as vertical centrifuge, hi-G dryer, screw pump, etc. KOSUN is capable of providing customers with three series as oil & gas drilling solids control equipment, centrifuges and drilling waste treatment equipment, including 25 categories of products, which are extensively used in oil & gas drilling and workover, coalbed methane drilling, shale gas drilling, water well, geothermal well drilling, trenchless horizontal directional crossing projects, mine gravel staged treatment, tailings treatment, rive dredging works, industrial waste water treatment, environmentally friendly sewage treatment, waste oil recovery, purification treatment, etc.