Jan 08, 2014

Drilling fluids is integral to the drilling process and has many functions, such as lubricating and cooling the drill bit as well as conveying the drilled cuttings away from the bore hole. These fluids are a mixture of various chemicals in a water or oil-based solution and can be very expensive to make. For both environmental reasons and reduction of the cost of drilling operations, drilling fluids losses are minimized by stripping them away from the drilled cuttings before the cuttings are disposed of, this is done using a multitude of specialized solids control equipment and drilling fluids mud tanks.

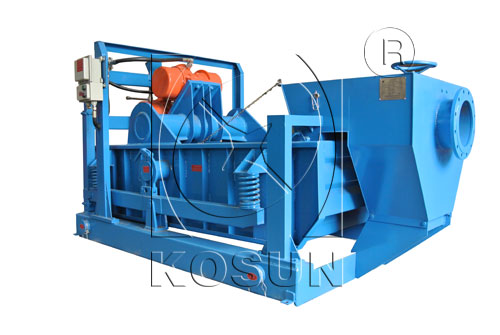

Shale shaker is the primary solids control equipment that removes drill cuttings from the drilling fluids in drilling fluids purification system. After that, there are other equipment,such as, oilfield desander, drilling mud desilter, decanter centrifuge, drilling fluids degasser, etc. It can remove cuttings above 75µm brought from the drilling well and the liquid with smaller particles will flow into tanks from where the fluids will flow into next solids control equipment for further treatment. There are many different designs and research into the best design constantly ongoing since solids control is vital in keeping down costs associated with the drilling fluids.

In oil drilling solids control system, the drilling fluids flows onto the shaker screen of oilfield drilling shale shaker from feeder to the terminal end, and the solids that are bigger than the mesh will be kept on the screen. The liquid phase with smaller particles will go through screen into the mud tank, and big solids then will be removed also through the terminal end of screen basket. The drilling fluids that come out from the borehole will continuously flow onto the screen to be treated. When the fluids or the liquid phase of the fluids spills from the terminal end of the shaker screen basket, it shows that the shale shaker comes to its processing limit.

This processing limit of shale shaker is determined by two factors:

(1) Liquid processing limit. This means the drilling fluids max. flowing rate that available for the shale shaker.

(2) Solid phase processing limit. This means the max. solids content that drilling fluids can carry to the terminal end.

Shale shaker screen is a kind of permeating medium, the process capacity of which is determined by:

(1) Screen basket motion trail;

(2) Flow conductivity;

(3) Effective filtration area.