Sep 17, 2013

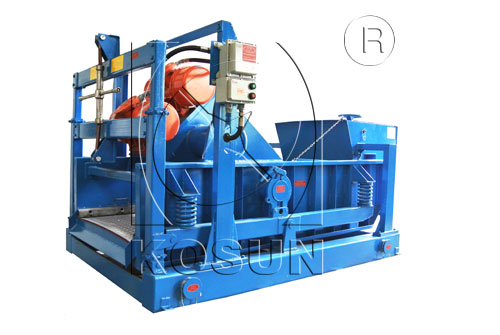

Shale shakers are the primary solids separation tool on a rig. After returning to the surface of the well, the used drilling fluids flows directly to the shale shakers where it begins to be processed. Once processed by the shale shakers, the drilling fluids is sent into the mud tanks where other solids control equipment begin to remove the finer solids from it. The solids removed by the shale shaker are discharged out of the discharge port into a separate holding tank where they await further treatment or disposal.

In general, in terms of the motion trail of shale shaker screen frame, shale shaker can be grouped into four types: circle screen, ordinary elliptic screen, linear screen and balanced elliptic screen.

Ordinary Elliptic Screen: also known as disequilibrium elliptic screen. Right above the centroid of the screen case there is a fixed excitation device. It requires the screen case to tilt an angle, by using gravity, it can clean up the sand constrainedly, and avoid the tendency of retrojecting of the sand. As a result, the slant of screen case improved in the mobile function of sand assuredly, but the handling capacity of drilling fluids has been reduced by the shale shaker. This is the major shortcoming of the ordinary elliptic screen.

Linear Screen: the two pieces of main shafts which have two eccentric blocks rotate synchronously and contraorbitally to produce linear vibration. Because the direction of linear screen vibrating is constant, the strangle particles come off difficultly, as a result, the phenomenon which called “sieve paste” will appear, the effective open area will be reduced, and decrease handling capacity, however when the sieve mesh number increases, the sieve paste phenomenon will be more seriously. Thus, when the linear screen uses super fine mesh, it will not content the demand of drilling fluids consumption.

Balanced Elliptic Screen: it’s a new screen type developed in recent years. The balanced elliptic screen combines the basic advantages of the circle screen and linear screen. The handling capacity of balanced elliptic screen is 20-30% more than the linear screen. It’s a more advanced drilling fluids shale shaker, and represents the current development direction of drilling fluids shale shaker.

KOSUN is professional solids control equipment and solids control system manufacturer in China. KOSUN's solids control equipment includes: shale shaker, vacuum degasser, mud cleaner, desander, desilter, centrifuge, shear pump, agitator, jet mud mixer, ignition device, mud tanks, pumps, etc.